115

0

45

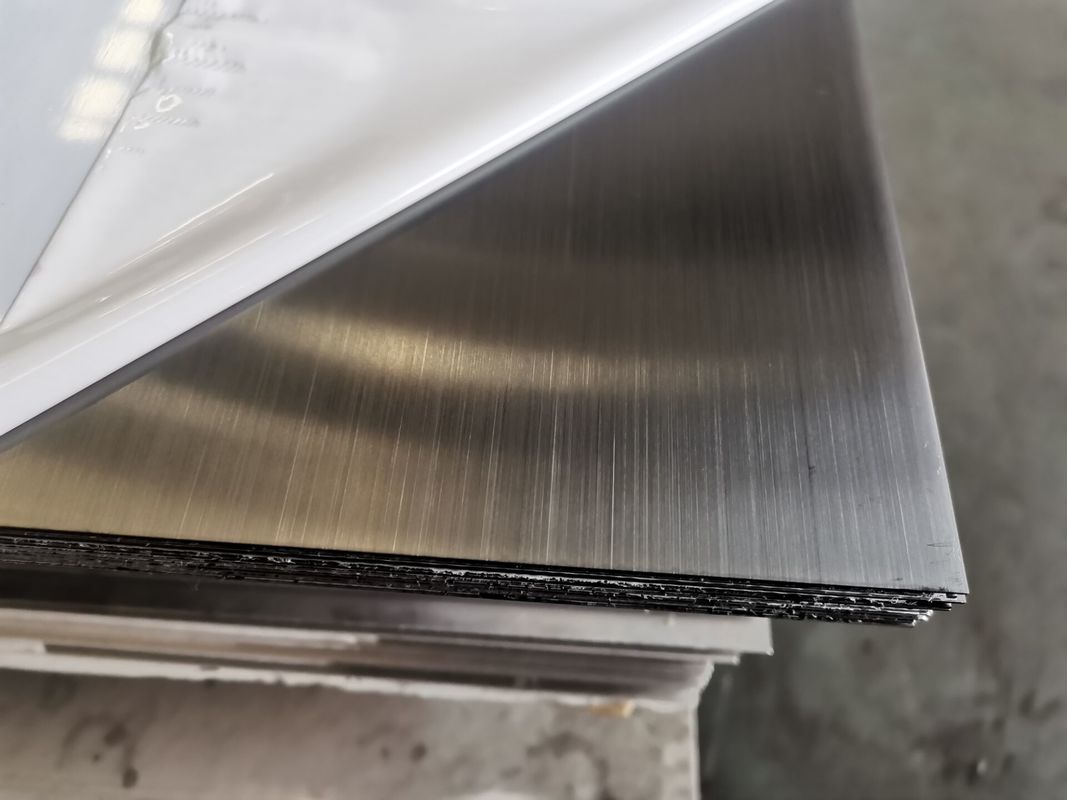

430 stainless steel

9

45

430 stainless steel, namely 430 stainless steel, is a kind of steel with good corrosion resistance and versatility. We can customize the size and offer bulk discounts at Wanzhi Steel with rich export experience, if you are looking for this kind of material, please feel free to contact us.

First, the chemical composition

The main chemical composition of 430 stainless steel includes carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), nickel (Ni), and chromium (Cr). Among them, the content of carbon is not more than 0.12%, the content of silicon is not more than 0.75%, the content of manganese is not more than 1.00%, the content of phosphorus is not more than 0.040%, the content of sulfur is not more than 0.030%, the content of nickel is not more than 0.60%, and the content of chromium is between 16.00% and 18.00%. These chemical compositions make 430 stainless steel has unique physical and chemical properties.

Second, physical properties

Density: the density of 430 stainless steel is about 7.7g/cm³.

Melting point: its melting point ranges between 1425~1510℃, but the melting point is usually mentioned as 1427℃.

Coefficient of Thermal Expansion: 430 stainless steel has a relatively small coefficient of thermal expansion, which makes it dimensionally stable in high temperature environments.

Thermal conductivity: the thermal conductivity of 430 stainless steel is better than austenitic stainless steel.

Third, mechanical properties

Tensile strength: the tensile strength σb (MPa) of 430 stainless steel is not less than 450MPa.

Yield strength: condition yield strength σ0.2 (MPa) is not less than 205MPa.

Elongation: elongation δ5 (%) not less than 22%.

Section shrinkage: section shrinkage ψ (%) is not less than 50%.

Hardness: Hardness HBS not more than 183.

Fourth, the characteristics and advantages

Corrosion resistance: 430 stainless steel has good corrosion resistance to various media including nitric acid and some organic acids. However, the corrosion resistance is best when its surface has a high degree of polishing. At the same time, it has high resistance to stress corrosion cracking. However, it should be noted that 430 stainless steel is not resistant to oxidation caused by chemicals in the air, so it may oxidize (rust) after a period of use due to unnatural factors.

Heat resistance: 430 stainless steel has good resistance to oxidation in intermittent service up to 870°C and continuous service up to 815°C. However, it may become brittle and require annealing after prolonged heating at 400~600℃.

Machinability: 430 stainless steel can be cold worked and hot worked. Cold working is relatively easy, but not as tough as 304 stainless steel. Hot working manufacturing methods such as forging should be carried out after uniform heating to 816~1038℃, then air cooled to room temperature and annealed.

Weldability: 430 stainless steel can be easily welded by all fusion methods, but it is recommended to preheat it to 150200℃. Annealing at 790815℃ can alleviate the embrittlement of the heated zone.

V. Application areas

Because 430 stainless steel has good corrosion resistance and processability, it is widely used in many fields. Specifically including:

Architectural decoration: such as decorative edge strips, etc.

Household appliances: such as washing machines, dishwashers, stoves, and other white and brown goods, as well as refrigerators, stove element brackets.

Fuel burner parts: burner parts for various fuel equipment.

Sanitary appliances: such as hot water tanks, hot water supply systems bicycle flywheels, and other household durable appliances.

In addition, 430 stainless steel is also used in the manufacture of a variety of power transformers, pulse transformers, magnetic amplifiers, converters, and other iron cores of the silicon steel thin strip working frequency above 400Hz. For example: Stainless Steel Mesh Screen, Perforated Stainless Steel Mesh, and stainless steel rope mesh.

In summary, 430 stainless steel is a kind of steel with excellent performance and a wide range of application areas.

430/304/200 series Stainless steel Sheet/Coil/ Strip/ Wire In Stock

Wanzhi Steel is one of the wholesale stainless steel manufacturers and suppliers in China, which stocks a wide range of SS products in 304, 316, 400, etc. Our product range includes stainless steel coils, sheets, strips, plates, etc. Due to its excellent corrosion resistance, smooth surface, high plasticity, and toughness, stainless steel is widely used in construction projects, automobiles, kitchenware, industrial equipment, food industry, etc. If you are looking for steel products, welcome to Contact Us!

First, the chemical composition

The main chemical composition of 430 stainless steel includes carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), nickel (Ni), and chromium (Cr). Among them, the content of carbon is not more than 0.12%, the content of silicon is not more than 0.75%, the content of manganese is not more than 1.00%, the content of phosphorus is not more than 0.040%, the content of sulfur is not more than 0.030%, the content of nickel is not more than 0.60%, and the content of chromium is between 16.00% and 18.00%. These chemical compositions make 430 stainless steel has unique physical and chemical properties.

Second, physical properties

Density: the density of 430 stainless steel is about 7.7g/cm³.

Melting point: its melting point ranges between 1425~1510℃, but the melting point is usually mentioned as 1427℃.

Coefficient of Thermal Expansion: 430 stainless steel has a relatively small coefficient of thermal expansion, which makes it dimensionally stable in high temperature environments.

Thermal conductivity: the thermal conductivity of 430 stainless steel is better than austenitic stainless steel.

Third, mechanical properties

Tensile strength: the tensile strength σb (MPa) of 430 stainless steel is not less than 450MPa.

Yield strength: condition yield strength σ0.2 (MPa) is not less than 205MPa.

Elongation: elongation δ5 (%) not less than 22%.

Section shrinkage: section shrinkage ψ (%) is not less than 50%.

Hardness: Hardness HBS not more than 183.

Fourth, the characteristics and advantages

Corrosion resistance: 430 stainless steel has good corrosion resistance to various media including nitric acid and some organic acids. However, the corrosion resistance is best when its surface has a high degree of polishing. At the same time, it has high resistance to stress corrosion cracking. However, it should be noted that 430 stainless steel is not resistant to oxidation caused by chemicals in the air, so it may oxidize (rust) after a period of use due to unnatural factors.

Heat resistance: 430 stainless steel has good resistance to oxidation in intermittent service up to 870°C and continuous service up to 815°C. However, it may become brittle and require annealing after prolonged heating at 400~600℃.

Machinability: 430 stainless steel can be cold worked and hot worked. Cold working is relatively easy, but not as tough as 304 stainless steel. Hot working manufacturing methods such as forging should be carried out after uniform heating to 816~1038℃, then air cooled to room temperature and annealed.

Weldability: 430 stainless steel can be easily welded by all fusion methods, but it is recommended to preheat it to 150200℃. Annealing at 790815℃ can alleviate the embrittlement of the heated zone.

V. Application areas

Because 430 stainless steel has good corrosion resistance and processability, it is widely used in many fields. Specifically including:

Architectural decoration: such as decorative edge strips, etc.

Household appliances: such as washing machines, dishwashers, stoves, and other white and brown goods, as well as refrigerators, stove element brackets.

Fuel burner parts: burner parts for various fuel equipment.

Sanitary appliances: such as hot water tanks, hot water supply systems bicycle flywheels, and other household durable appliances.

In addition, 430 stainless steel is also used in the manufacture of a variety of power transformers, pulse transformers, magnetic amplifiers, converters, and other iron cores of the silicon steel thin strip working frequency above 400Hz. For example: Stainless Steel Mesh Screen, Perforated Stainless Steel Mesh, and stainless steel rope mesh.

In summary, 430 stainless steel is a kind of steel with excellent performance and a wide range of application areas.

430/304/200 series Stainless steel Sheet/Coil/ Strip/ Wire In Stock

Wanzhi Steel is one of the wholesale stainless steel manufacturers and suppliers in China, which stocks a wide range of SS products in 304, 316, 400, etc. Our product range includes stainless steel coils, sheets, strips, plates, etc. Due to its excellent corrosion resistance, smooth surface, high plasticity, and toughness, stainless steel is widely used in construction projects, automobiles, kitchenware, industrial equipment, food industry, etc. If you are looking for steel products, welcome to Contact Us!

Signatur