20

0

0

What Are The Various Designs Of Concrete Crusher Machines

9

0

Concrete crushing is amongst the most popular stages of several constructions projects. There are various varieties of concrete crusher machines, each one having its specific design and technical features. This post takes a good look at the various types of concrete crusher machines that will help you understand what one works best for your very own projects.

The fundamental job of most concrete crushers would be to breakdown blocks of concrete waste into smaller pieces that are simpler to handle. These smaller concrete chunks are quicker to transport or dump. As large blocks are impossible to break as a result of really small pieces all at once, the procedure needs to undergo several stages. Each of these stages needs a different style of concrete crusher.

To begin with, the demolition process takes a device to break down substantial blocks into smaller pieces. This is usually the job of the jaw crusher. A jaw crusher works like a giant human jaw, chewing on concrete slabs and turning them into smaller pieces. The appearance of a jaw crusher is easy and simple.

Next, there are actually cone crushers that take this job a stride further. The style of a cone crusher comes with a concave area having a rotating spindle. Workers fill this piece of equipment with concrete pieces by dropping them at the top of the appliance. The device crushes down these pieces into smaller ones. These smaller pieces fall from the cone and also the crushing process continues on until they become as small as to successfully pass from the chute and in to a hopper. Cone crushers may be found in many sizes. Many of them are rather large, but additionally, there are portable types of cone crushers, suitable for smaller projects.

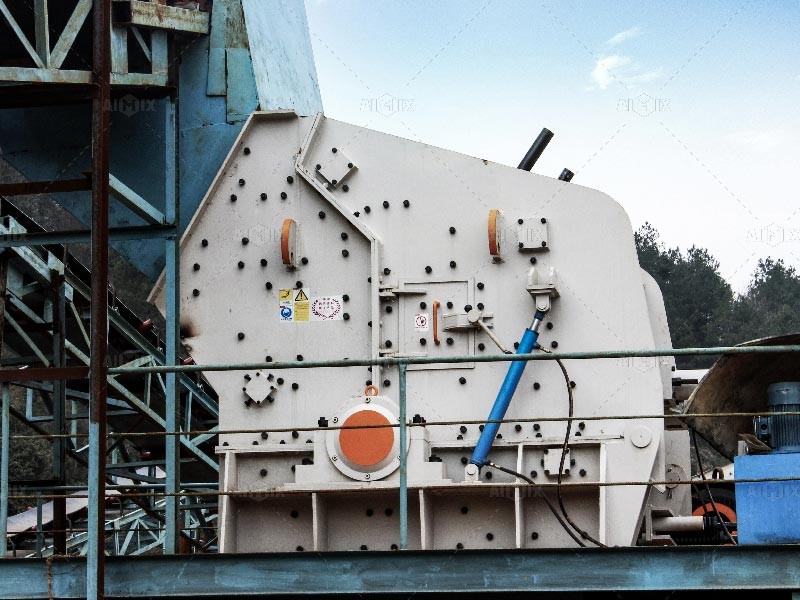

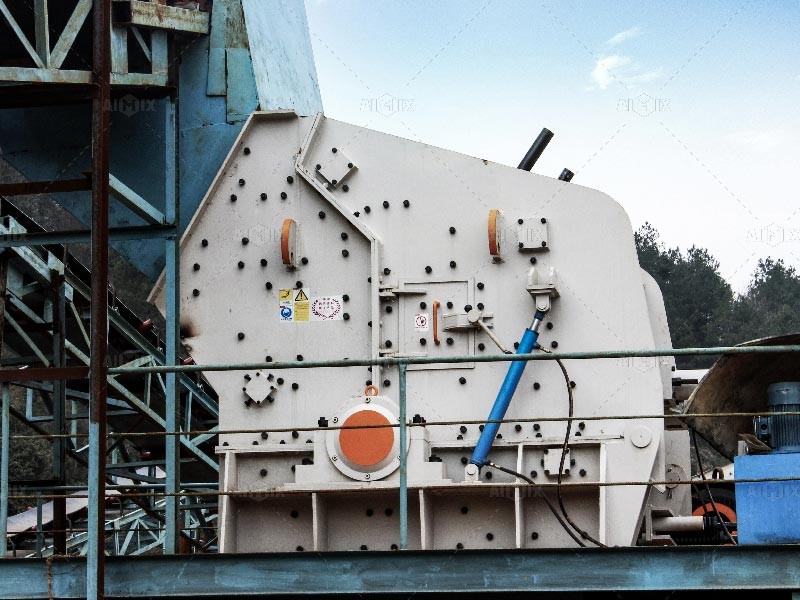

Then there are also impact crushers in AIMIX Group, using their specific design that utilizes impact force to get rid of down concrete. This design has two variations: horizontal and vertical. Horizontal impact crushers retain the concrete within a special container. This machine features several hammers mounted on a spinning rotor. These hammers hit the concrete to break it into smaller chunks that can pas through some openings on the side of the appliance. Their reduction ratio is of 25/1, that is pretty good in any way. This style of concrete crusher would work for softer materials, but this doesn't help it become less efficient.

As you can tell, there are actually different designs of machines, each of them using its specific functions, advantages, and drawbacks. That is why you have to plan your demolition projects earlier on, so as to make sure you select the right equipment for each and every stage with this process. Usually, you'll probably need multiple model of crusher. You'll begin with the jaw crusher to destroy across the concrete into pieces that you could then throw in a cone crusher. In case of softer materials, you'll obtain greatest results by utilizing a positive change crusher. In case the size isn't very simple to access, you may want to use a mobile concrete crusher to do the job.

The fundamental job of most concrete crushers would be to breakdown blocks of concrete waste into smaller pieces that are simpler to handle. These smaller concrete chunks are quicker to transport or dump. As large blocks are impossible to break as a result of really small pieces all at once, the procedure needs to undergo several stages. Each of these stages needs a different style of concrete crusher.

To begin with, the demolition process takes a device to break down substantial blocks into smaller pieces. This is usually the job of the jaw crusher. A jaw crusher works like a giant human jaw, chewing on concrete slabs and turning them into smaller pieces. The appearance of a jaw crusher is easy and simple.

Next, there are actually cone crushers that take this job a stride further. The style of a cone crusher comes with a concave area having a rotating spindle. Workers fill this piece of equipment with concrete pieces by dropping them at the top of the appliance. The device crushes down these pieces into smaller ones. These smaller pieces fall from the cone and also the crushing process continues on until they become as small as to successfully pass from the chute and in to a hopper. Cone crushers may be found in many sizes. Many of them are rather large, but additionally, there are portable types of cone crushers, suitable for smaller projects.

Then there are also impact crushers in AIMIX Group, using their specific design that utilizes impact force to get rid of down concrete. This design has two variations: horizontal and vertical. Horizontal impact crushers retain the concrete within a special container. This machine features several hammers mounted on a spinning rotor. These hammers hit the concrete to break it into smaller chunks that can pas through some openings on the side of the appliance. Their reduction ratio is of 25/1, that is pretty good in any way. This style of concrete crusher would work for softer materials, but this doesn't help it become less efficient.

As you can tell, there are actually different designs of machines, each of them using its specific functions, advantages, and drawbacks. That is why you have to plan your demolition projects earlier on, so as to make sure you select the right equipment for each and every stage with this process. Usually, you'll probably need multiple model of crusher. You'll begin with the jaw crusher to destroy across the concrete into pieces that you could then throw in a cone crusher. In case of softer materials, you'll obtain greatest results by utilizing a positive change crusher. In case the size isn't very simple to access, you may want to use a mobile concrete crusher to do the job.