27

0

0

Rolling into Tomorrow: Exploring the Wonders of Tyre Pyrolysis Plant

28

0

In the labyrinth of waste management, a technological marvel is silently making waves – the tyre pyrolysis plant. Imagine a world where old tires don't end up as environmental eyesores, but rather embark on a journey of rebirth, transformed into valuable resources. Let's unravel the secrets of this eco-friendly enigma.

Dance of Thermodynamics: Tyre Pyrolysis Unveiled

At its core, tyre pyrolysis is an alchemical dance of thermodynamics. The process involves subjecting discarded tires to high temperatures in the absence of oxygen, causing them to undergo a metamorphic transformation. This thermal ballet results in the decomposition of tires into valuable byproducts, including pyrolytic oil, carbon black, and syngas.

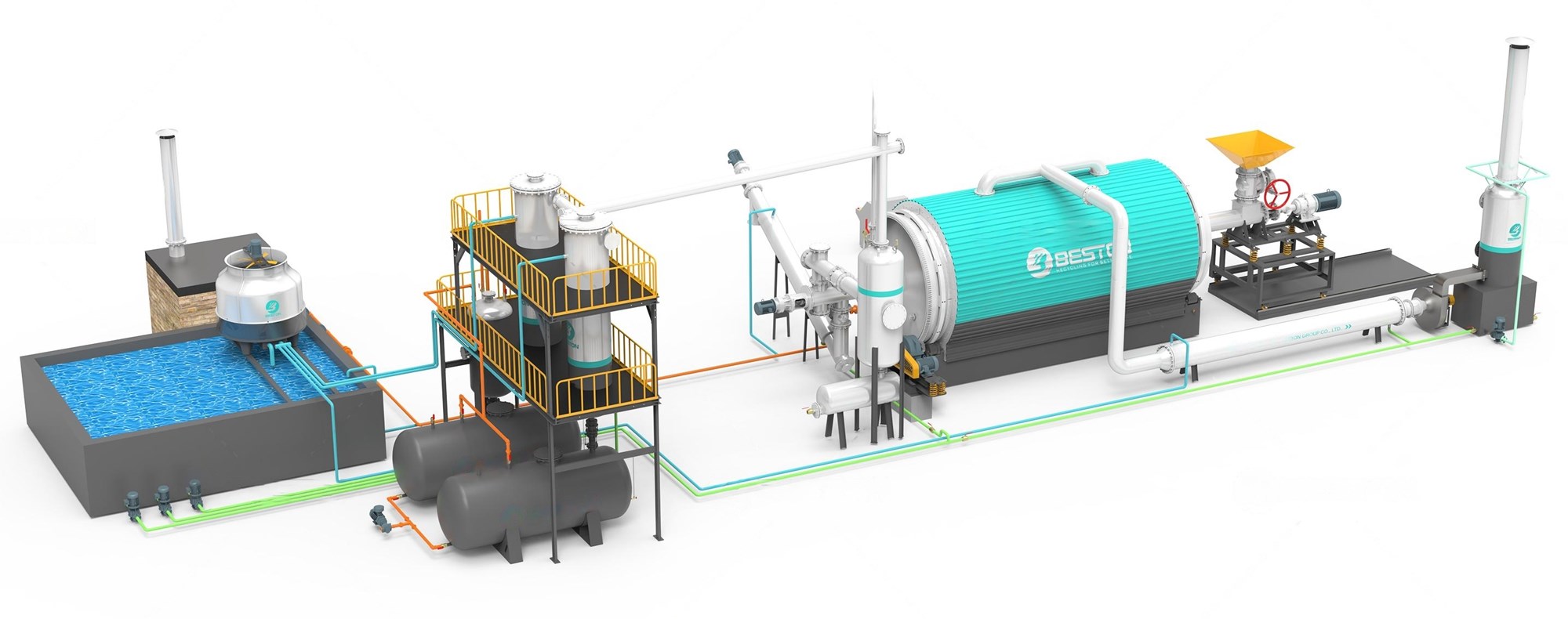

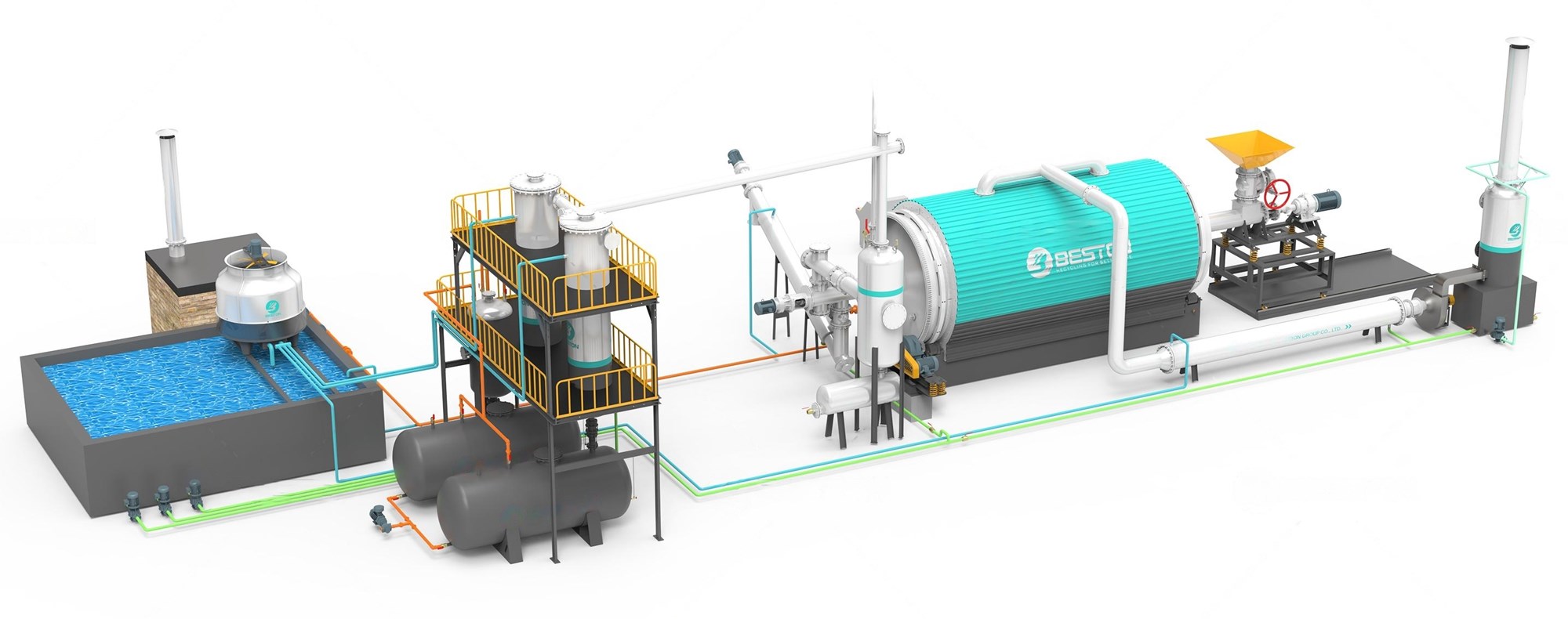

Tyre Pyrolysis Plant: Anatomy of Innovation

The Reactor Chamber

The heart of the operation lies within the reactor chamber, where the magic of tyre pyrolysis unfolds. Tires, often seen as nothing more than rubber relics, find themselves in this high-temperature crucible, breaking down into their elemental components.

Pyrolytic Oil Extraction

One of the crown jewels extracted from this process is pyrolytic oil. This liquid gold, with its myriad applications, becomes a cornerstone in the economic viability of the tyre pyrolysis plant. From fuel production to industrial lubricants, the versatility of pyrolytic oil adds a layer of sustainability to the recycling narrative.

Carbon Black Treasure Trove

Tyre pyrolysis unlocks the hidden potential of carbon black, a substance integral to the tire manufacturing process. Once relegated to the realm of waste, carbon black emerges from the pyrolytic crucible as a valuable resource, ready to be reintegrated into various industrial applications.

Financial Alchemy: Tyre Pyrolysis Plant Cost Considerations

Capital Investment

Embarking on the journey toward sustainable waste management involves a financial leap of faith. The tyre pyrolysis plant cost encompasses the initial capital investment required to set up the machinery, reactor chambers, and the intricate web of technologies orchestrating the tire-to-treasure transformation.

Operational Efficiency

Beyond the upfront costs, the day-to-day operational efficiency of the tyre pyrolysis plant plays a starring role in the financial narrative. Efficient energy utilization, streamlined processes, and maintenance considerations all contribute to the ongoing operational costs, influencing the long-term economic viability.

Green Innovation in Action: Beyond Tyre Pyrolysis Plant Cost

Environmental Impact

The beauty of the tyre pyrolysis plant extends beyond its financial dimensions. It's a hero in the war against environmental degradation. By diverting tires from landfills and repurposing them into valuable commodities, it stands as a beacon of sustainable waste management.

Global Sustainability Goals

In a world grappling with the consequences of rampant consumerism, the tyre pyrolysis plant emerges as a potent ally in achieving global sustainability goals. It aligns with the circular economy ethos, where waste becomes a valuable resource, closing the loop on the linear take-make-dispose model.

Future Horizons: Tyre Pyrolysis Plant Innovation

As technology evolves, so does the landscape of waste management. Emerging innovations in tyre pyrolysis plants promise increased efficiency, reduced environmental footprint, and a broader spectrum of valuable byproducts. From modular designs to advanced catalytic processes, the future holds exciting prospects for tire recycling.

Dance of Thermodynamics: Tyre Pyrolysis Unveiled

At its core, tyre pyrolysis is an alchemical dance of thermodynamics. The process involves subjecting discarded tires to high temperatures in the absence of oxygen, causing them to undergo a metamorphic transformation. This thermal ballet results in the decomposition of tires into valuable byproducts, including pyrolytic oil, carbon black, and syngas.

Tyre Pyrolysis Plant: Anatomy of Innovation

The Reactor Chamber

The heart of the operation lies within the reactor chamber, where the magic of tyre pyrolysis unfolds. Tires, often seen as nothing more than rubber relics, find themselves in this high-temperature crucible, breaking down into their elemental components.

Pyrolytic Oil Extraction

One of the crown jewels extracted from this process is pyrolytic oil. This liquid gold, with its myriad applications, becomes a cornerstone in the economic viability of the tyre pyrolysis plant. From fuel production to industrial lubricants, the versatility of pyrolytic oil adds a layer of sustainability to the recycling narrative.

Carbon Black Treasure Trove

Tyre pyrolysis unlocks the hidden potential of carbon black, a substance integral to the tire manufacturing process. Once relegated to the realm of waste, carbon black emerges from the pyrolytic crucible as a valuable resource, ready to be reintegrated into various industrial applications.

Financial Alchemy: Tyre Pyrolysis Plant Cost Considerations

Capital Investment

Embarking on the journey toward sustainable waste management involves a financial leap of faith. The tyre pyrolysis plant cost encompasses the initial capital investment required to set up the machinery, reactor chambers, and the intricate web of technologies orchestrating the tire-to-treasure transformation.

Operational Efficiency

Beyond the upfront costs, the day-to-day operational efficiency of the tyre pyrolysis plant plays a starring role in the financial narrative. Efficient energy utilization, streamlined processes, and maintenance considerations all contribute to the ongoing operational costs, influencing the long-term economic viability.

Green Innovation in Action: Beyond Tyre Pyrolysis Plant Cost

Environmental Impact

The beauty of the tyre pyrolysis plant extends beyond its financial dimensions. It's a hero in the war against environmental degradation. By diverting tires from landfills and repurposing them into valuable commodities, it stands as a beacon of sustainable waste management.

Global Sustainability Goals

In a world grappling with the consequences of rampant consumerism, the tyre pyrolysis plant emerges as a potent ally in achieving global sustainability goals. It aligns with the circular economy ethos, where waste becomes a valuable resource, closing the loop on the linear take-make-dispose model.

Future Horizons: Tyre Pyrolysis Plant Innovation

As technology evolves, so does the landscape of waste management. Emerging innovations in tyre pyrolysis plants promise increased efficiency, reduced environmental footprint, and a broader spectrum of valuable byproducts. From modular designs to advanced catalytic processes, the future holds exciting prospects for tire recycling.