45

0

0

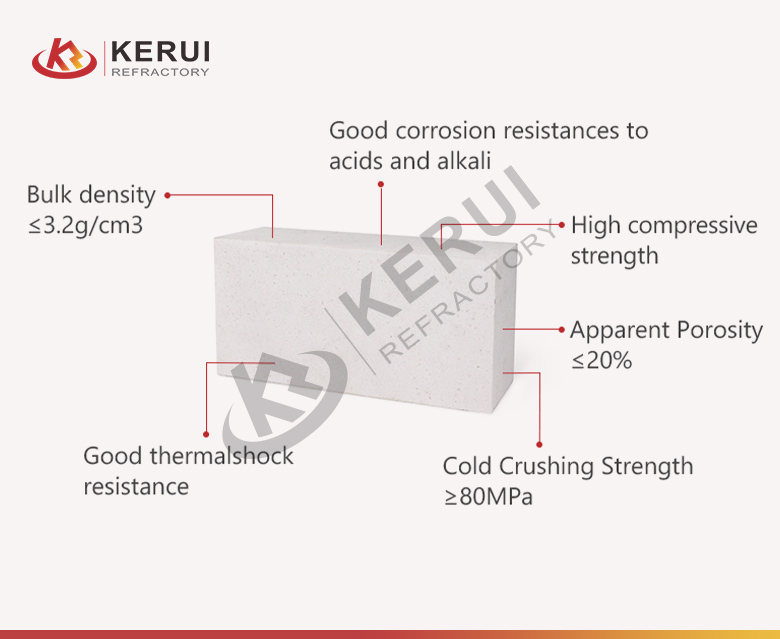

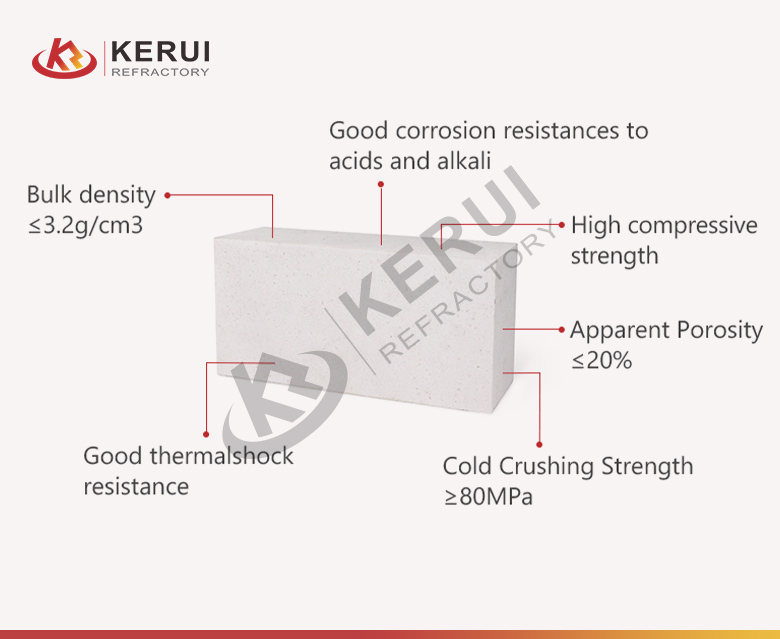

Properties of Corundum Brick

4

0

Corundum brick, renowned for its exceptional properties, stands out as a key material in various industrial applications. Derived primarily from high-purity alumina and produced through advanced manufacturing processes, corundum brick possesses unique characteristics that make it indispensable in environments requiring high temperature resistance, mechanical strength, and chemical stability.

High Temperature Resistance

Corundum brick excels in environments where temperatures soar. With a melting point exceeding 2000°C (3632°F), it remains stable and retains its structural integrity even under extreme heat. These properties of corundum brick make it ideal for lining furnaces, kilns, and reactors where maintaining structural integrity at elevated temperatures is critical.

Excellent Mechanical Strength

The crystalline structure of corundum imparts exceptional mechanical strength to the brick. It withstands mechanical stress, abrasion, and thermal shock without compromising its shape or integrity. This durability ensures longevity and reliability in demanding industrial processes.

Chemical Inertness

Corundum brick exhibits high resistance to chemical corrosion. It is largely inert to acids, alkalis, and other harsh chemicals, making it suitable for applications where exposure to corrosive substances is unavoidable. This property extends its lifespan and minimizes maintenance costs in corrosive environments.

Thermal Insulation Properties

While corundum brick is renowned for its heat resistance, it also offers good thermal insulation. Its low thermal conductivity helps in conserving energy and maintaining uniform refractory temperature within industrial equipment, thereby enhancing operational efficiency.

Low Porosity and Dense Structure

Due to its dense composition and low porosity, corundum brick prevents the penetration of gases and liquids, which could otherwise compromise its structural integrity. This characteristic also contributes to its excellent thermal shock resistance, as rapid temperature changes do not cause cracking or degradation.

Versatility in Applications

The versatility of corundum brick extends across various industries including metallurgy, ceramics, petrochemicals, and glass manufacturing. It serves as linings in blast furnaces, kilns, incinerators, and reactors where its combination of high temperature resistance, mechanical strength, and chemical inertness is highly valued.

Ease of Installation and Maintenance

Corundum bricks are designed for easy installation and maintenance. Their standardized shapes and sizes facilitate straightforward construction and replacement processes, reducing downtime and labor costs during maintenance operations.

Conclusion

In conclusion, corundum brick stands as a testament to advanced materials engineering, offering a unique blend of high temperature resistance, mechanical strength, chemical inertness, and thermal insulation. Its properties not only ensure reliable performance in harsh industrial environments but also contribute to increased efficiency and reduced operational costs over the long term. As industries continue to push the boundaries of temperature and chemical resistance, corundum brick remains an indispensable choice for engineers and manufacturers seeking durability and performance excellence.

High Temperature Resistance

Corundum brick excels in environments where temperatures soar. With a melting point exceeding 2000°C (3632°F), it remains stable and retains its structural integrity even under extreme heat. These properties of corundum brick make it ideal for lining furnaces, kilns, and reactors where maintaining structural integrity at elevated temperatures is critical.

Excellent Mechanical Strength

The crystalline structure of corundum imparts exceptional mechanical strength to the brick. It withstands mechanical stress, abrasion, and thermal shock without compromising its shape or integrity. This durability ensures longevity and reliability in demanding industrial processes.

Chemical Inertness

Corundum brick exhibits high resistance to chemical corrosion. It is largely inert to acids, alkalis, and other harsh chemicals, making it suitable for applications where exposure to corrosive substances is unavoidable. This property extends its lifespan and minimizes maintenance costs in corrosive environments.

Thermal Insulation Properties

While corundum brick is renowned for its heat resistance, it also offers good thermal insulation. Its low thermal conductivity helps in conserving energy and maintaining uniform refractory temperature within industrial equipment, thereby enhancing operational efficiency.

Low Porosity and Dense Structure

Due to its dense composition and low porosity, corundum brick prevents the penetration of gases and liquids, which could otherwise compromise its structural integrity. This characteristic also contributes to its excellent thermal shock resistance, as rapid temperature changes do not cause cracking or degradation.

Versatility in Applications

The versatility of corundum brick extends across various industries including metallurgy, ceramics, petrochemicals, and glass manufacturing. It serves as linings in blast furnaces, kilns, incinerators, and reactors where its combination of high temperature resistance, mechanical strength, and chemical inertness is highly valued.

Ease of Installation and Maintenance

Corundum bricks are designed for easy installation and maintenance. Their standardized shapes and sizes facilitate straightforward construction and replacement processes, reducing downtime and labor costs during maintenance operations.

Conclusion

In conclusion, corundum brick stands as a testament to advanced materials engineering, offering a unique blend of high temperature resistance, mechanical strength, chemical inertness, and thermal insulation. Its properties not only ensure reliable performance in harsh industrial environments but also contribute to increased efficiency and reduced operational costs over the long term. As industries continue to push the boundaries of temperature and chemical resistance, corundum brick remains an indispensable choice for engineers and manufacturers seeking durability and performance excellence.