35

0

0

5 Techniques to Improve Bubble Alumina Bricks

10

Chaohua Refractory Industry Zone, Xinmi City, Henan Province, China.

0

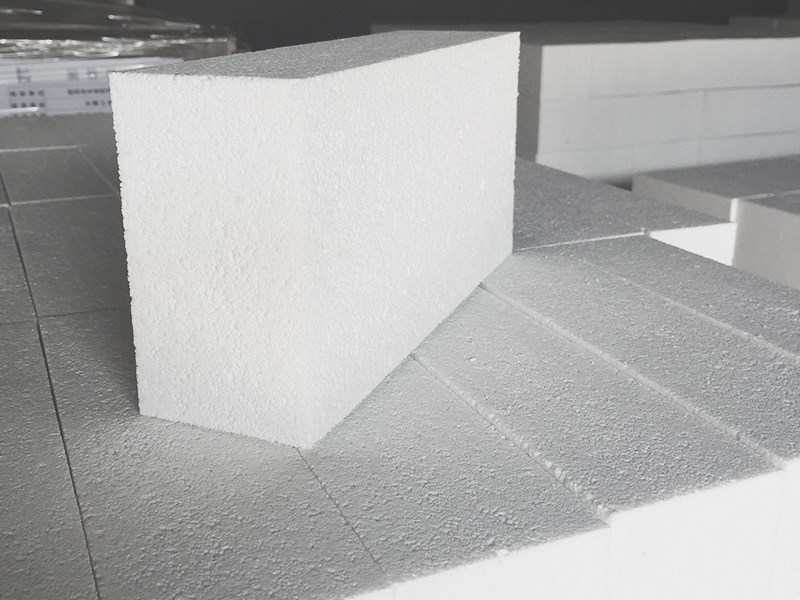

Bubble alumina bricks, renowned for their lightweight composition, exceptional insulation properties, high-temperature resistance, and low thermal conductivity, are extensively utilized in various industrial applications such as furnaces, kilns, and high-temperature processing equipment. To augment the performance and durability of these bricks, several techniques can be employed during manufacturing and installation. In this article, we will explore five techniques that can enhance bubble alumina bricks, ensuring optimal thermal insulation and prolonged service life.

Meticulous Raw Material Selection

The quality of the raw materials used significantly impacts the performance of bubble alumina bricks. Opt for high-purity alumina powders with controlled particle size distribution and low impurity levels. Additionally, carefully select a binder material that ensures proper bonding without compromising the brick's insulating properties. Thoughtfully chosen raw materials contribute to better thermal insulation, improved mechanical strength, and enhanced resistance to thermal shocks.

Optimization of Bubble Formation

The presence of evenly distributed and well-distributed closed-cell bubbles is crucial for the insulating properties of great bubble alumina brick. During the manufacturing process, it is imperative to optimize bubble formation. This can be achieved by meticulously controlling the temperature and pressure conditions during the foaming stage. Appropriate control ensures consistent bubble sizes, reduced porosity, and improved insulating performance of the bricks.

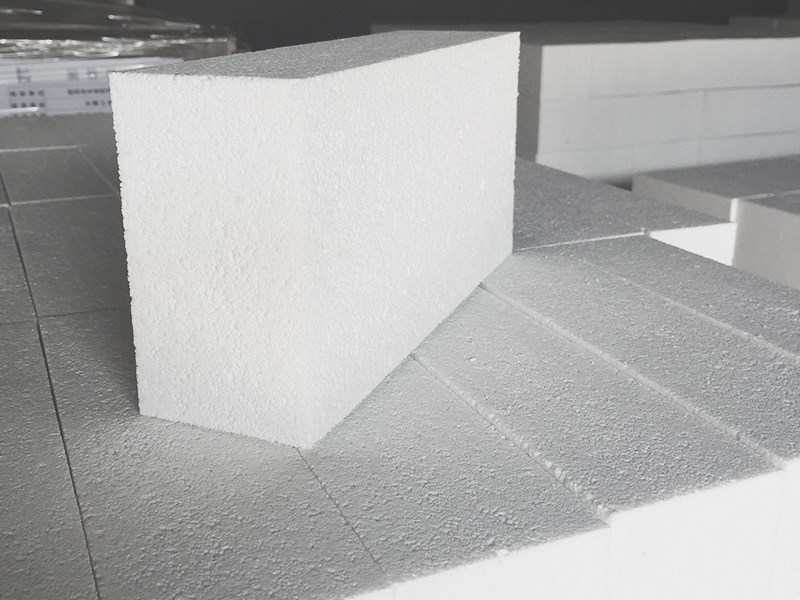

Controlled Drying and Firing

The drying and firing stages significantly influence the final properties of bubble alumina bricks. It is essential to adhere to controlled and optimized drying procedures to prevent cracking or warping of the bricks. Slow and uniform drying at a controlled rate helps minimize thermal stresses and ensures dimensional stability. Similarly, during firing, meticulously control the temperature ramp-up and cooling rates to avoid thermal shock and maintain the integrity of the bricks. In addition, fine insulating soft fire brick also has good quality.

Prudent Installation Techniques

Correct installation techniques play a vital role in maximizing the performance of bubble alumina bricks. Pay meticulous attention to proper brick placement, ensuring tight joints and good contact between bricks. Utilize suitable refractory mortar or adhesive to establish a robust bond between the bricks, thereby reducing heat leakage. Adequate curing and drying of the installed bricks are also crucial to preserve their insulating properties. Adhering to manufacturer guidelines for installation techniques and engaging experienced personnel will yield optimal results.

Regular Maintenance and Inspection

Regular maintenance and inspection of bubble alumina brick linings are indispensable for their long-term performance. Periodically monitor the condition of the bricks, scrutinizing for signs of wear, cracks, or damage. Promptly repair or replace any damaged bricks to uphold the integrity of the lining. Regular cleaning of the bricks and removing any deposits or contaminants will also aid in preserving their insulating properties.

In conclusion, implementing these techniques can significantly enhance the performance and longevity of bubble alumina bricks. By thoughtfully selecting high-quality raw materials, optimizing bubble formation, controlling drying and firing processes, employing proper installation techniques, and conducting regular maintenance and inspections, the insulating properties and thermal efficiency of bubble alumina bricks of Keruigroupcan be elevated. Remember to consult manufacturers or industry experts for specific guidelines and recommendations tailored to your particular application.

Meticulous Raw Material Selection

The quality of the raw materials used significantly impacts the performance of bubble alumina bricks. Opt for high-purity alumina powders with controlled particle size distribution and low impurity levels. Additionally, carefully select a binder material that ensures proper bonding without compromising the brick's insulating properties. Thoughtfully chosen raw materials contribute to better thermal insulation, improved mechanical strength, and enhanced resistance to thermal shocks.

Optimization of Bubble Formation

The presence of evenly distributed and well-distributed closed-cell bubbles is crucial for the insulating properties of great bubble alumina brick. During the manufacturing process, it is imperative to optimize bubble formation. This can be achieved by meticulously controlling the temperature and pressure conditions during the foaming stage. Appropriate control ensures consistent bubble sizes, reduced porosity, and improved insulating performance of the bricks.

Controlled Drying and Firing

The drying and firing stages significantly influence the final properties of bubble alumina bricks. It is essential to adhere to controlled and optimized drying procedures to prevent cracking or warping of the bricks. Slow and uniform drying at a controlled rate helps minimize thermal stresses and ensures dimensional stability. Similarly, during firing, meticulously control the temperature ramp-up and cooling rates to avoid thermal shock and maintain the integrity of the bricks. In addition, fine insulating soft fire brick also has good quality.

Prudent Installation Techniques

Correct installation techniques play a vital role in maximizing the performance of bubble alumina bricks. Pay meticulous attention to proper brick placement, ensuring tight joints and good contact between bricks. Utilize suitable refractory mortar or adhesive to establish a robust bond between the bricks, thereby reducing heat leakage. Adequate curing and drying of the installed bricks are also crucial to preserve their insulating properties. Adhering to manufacturer guidelines for installation techniques and engaging experienced personnel will yield optimal results.

Regular Maintenance and Inspection

Regular maintenance and inspection of bubble alumina brick linings are indispensable for their long-term performance. Periodically monitor the condition of the bricks, scrutinizing for signs of wear, cracks, or damage. Promptly repair or replace any damaged bricks to uphold the integrity of the lining. Regular cleaning of the bricks and removing any deposits or contaminants will also aid in preserving their insulating properties.

In conclusion, implementing these techniques can significantly enhance the performance and longevity of bubble alumina bricks. By thoughtfully selecting high-quality raw materials, optimizing bubble formation, controlling drying and firing processes, employing proper installation techniques, and conducting regular maintenance and inspections, the insulating properties and thermal efficiency of bubble alumina bricks of Keruigroupcan be elevated. Remember to consult manufacturers or industry experts for specific guidelines and recommendations tailored to your particular application.

Signatur